Quality and reliability

A-CONTRACT’s quality management system complies with the national standard of the Russian Federation GOST R ISO 9001:2015.

Quality management system allows the company to maintain high quality production and service standards and assures customers and partners that they are dealing with a capable, reliable and successful partner.

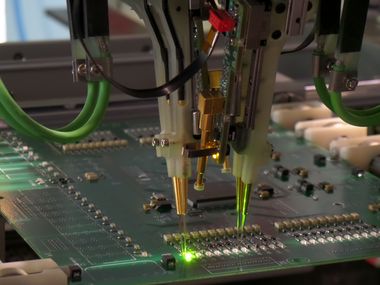

Multi-stage Quality Control System

The multi-stage quality control methods, technologies and equipment used in A-CONTRACT's facilities allows us to monitor the quality of PCBAs at each stage in the manufacturing process and guarantee the high quality of our products. The quality control processes apply throughout the PCBA manufacturing process: from inspection of incoming electronic components, PCBs and materials, to box build and final assembly.

1. DFM analysis

2. PCB electrical control

3. Impedance control

4. Incoming PCB inspection before assembly

5. Incoming inspection of electronic component

6. Control of stencil printing process using SPI-AOI systems

7. Visual control

PCBA quality control during the PCB assembly process. Assessment of the quality of soldering in accordance with the IPC-610 standard.

8. X-Ray and 3D X-Ray Inspection

Non-invasive monitoring to locate PCBA failures.

9. AOI

Inspection of solder joints using lead free technology. Monitoring of component with a size of less than 0201, and a pitch of less than 0.3 mm using advanced 3-D technology. Evaluation of the quality of solder joints after reflow and component installation in accordance with the criteria of IPC-A-610 quality standard.

10. ICT

Detection and localization of defects in electronic components without the supply of operating voltages.

11. Boundary scan JTAG

Use of a JTAG interface to identify defects in chip assembly. This technology is used when there physical access to the terminals of the electronic components installed on the printed circuit board is impossible.

12. Cleaning quality control

Identification of the presence of flux activator residues on the surface of electronic components.

13. Functional control

Checking that the device’s operational parameters comply with the specified requirements. A stand can be produced to carry out functional testing of your electronic components.