1. Full range of EMS services

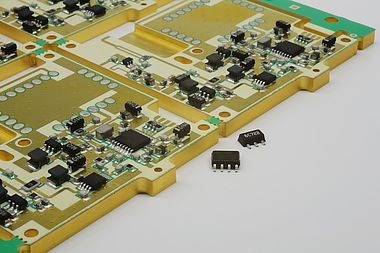

2. Printed circuit boards of any level of complexity

- DFM analysis

- PCB data processing for pre-production engineering

- PCB design and redesign

- PCBs of up to 40 layers

- RF / Microwave PCBs

- Impedance control

- PCB manufacturing using lead-free and mixed technologies

- Prototype PCB production

- Mass production of PCBs of any complexity

- Cleaning

- Laser marking of PCBs

- Conformal coating

3. PCB assembly

- Surface mounting stencil design

- PCB SMT and THT assembly

- PCB PoP and BGA, PGA, LGA etc. assembly

- Reflow soldering in convection and vapor-phase ovens, selective soldering, hand mounting

- PCB assembly using both non-lead-free lead-free technologies

- Assembly of components from size 01005 to 200x125mm

- BGA, µBGA, Flip Chip, CSP, TQFP and Fine pitch package assembly and reworking

- BGA laser reballing

- Mass production of SHF PCBAs

- PCBA cleaning

- PCBA conformal coating. Selective automatic conformal coating

- All types of PCBA testing, inspection and control

- visual and automated optical inspection

- stencil printing process control

- X-ray inspection

- in-circuit testing (ICT)

- functional control and boundary scan JTAG

- Design and manufacture of stands for functional control

- PCBA testing

- Box build

- Traceability at all stages of production